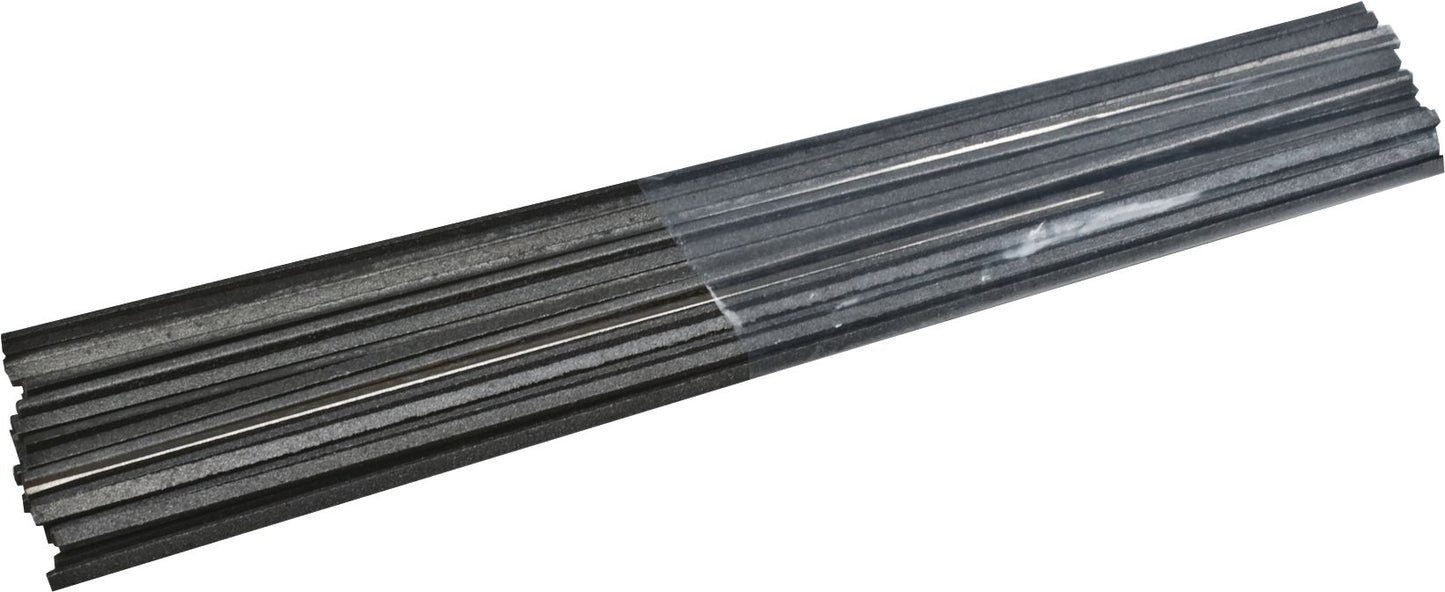

22 Cast Iron Bare Brazing Rod 3/16"

(Pack of

5.0)

A selection of brazing alloys for joining cast iron and brazing sheet metal.

Superior Advantages

• Solid, dense deposits that can be machined

• Free-flowing for thin lapping and butted metal joining

• No base metal dilution making tough cast iron repairs possible

“True Color Match” Cast Iron

Tensile Strength: 53,000 PSIHardness: Rc 18-20Bonding Temperature: 2,300°F (1,260°C)Recommended Flux: F22

Typical Applications

• Sheet metal and auto body repairs

• Engine heads and blocks

• Piping, plumbing and pumps

• Gears, sprockets and pulleys

Usage ProcedureUse neutral flame and preheat broad area along braze line. Concentrate flame on rod end and allow weld drops to flow on joint. Continue heating until it wets out and continue process. If a second layer is required, hold torch parallel to the work and apply drop-by-drop. When working with cast iron, avoid localized heating and cover finished braze to retard cooling process.

Couldn't load pickup availability

California Proposition 65: Not Applicable

www.P65Warnings.ca.gov

Catalog Page#: 13-29

Frequently Bought Together

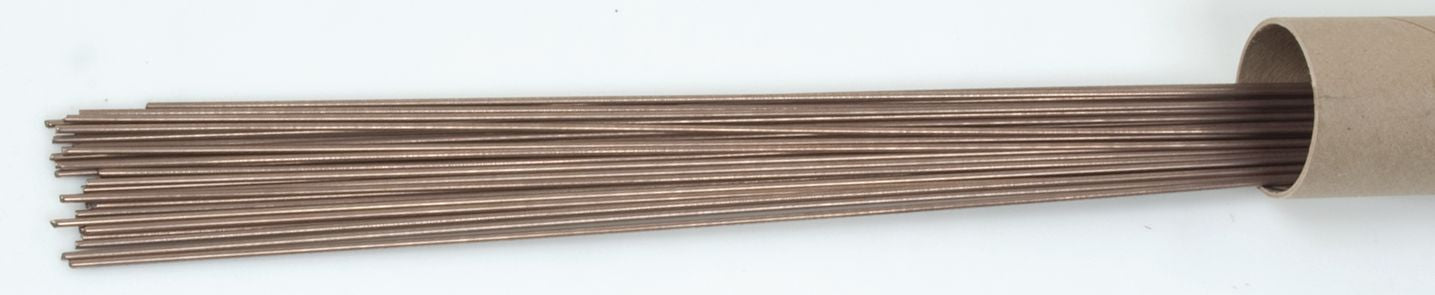

201 The Elite Bare Brazing Alloy 1/16X18

Couldn't load pickup availability

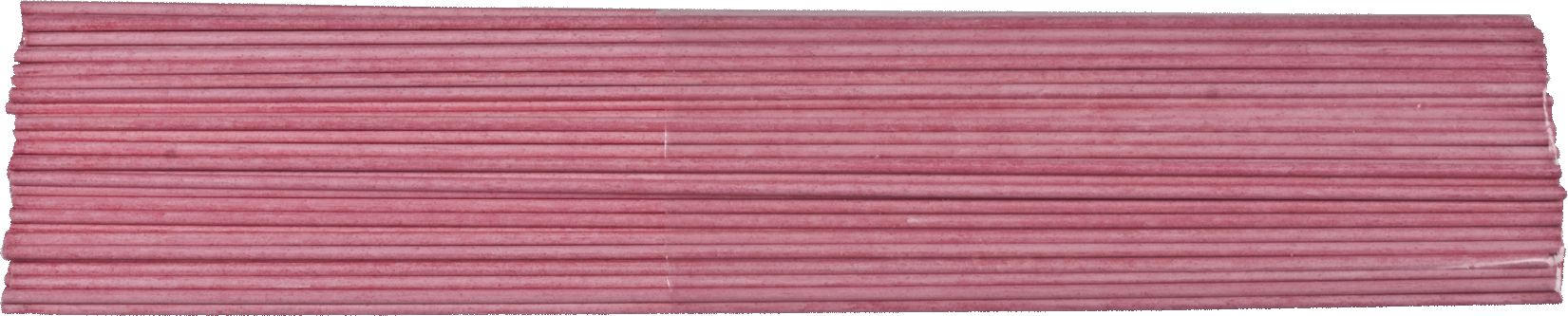

40 High Silver Flux Coated Brazing Rod 1/16"

Couldn't load pickup availability

44 Silver Bare Brazing Rod 3/32"

Couldn't load pickup availability

Butt Connector 16 to 14 AWG Blue

Couldn't load pickup availability

Butt Connector 22 to 18 AWG Red

Couldn't load pickup availability

Rechargeable Neck Light

Couldn't load pickup availability

30 Copper and Steel Flux Coated Brazing Rod 1/8"

Couldn't load pickup availability

23 Copper and Steel Flux Coated Brazing Rod 3/32"

Couldn't load pickup availability

23 Copper and Steel Flux Coated Brazing Rod 1/8"

Couldn't load pickup availability

Rosin Core Solder 0.032"

Couldn't load pickup availability

Solid Solder 1/32"

Couldn't load pickup availability

Flint For Spring Loaded Trigger Torch Lighter

Couldn't load pickup availability

Product Description

A selection of brazing alloys for joining cast iron and brazing sheet metal.Superior Advantages

• Solid, dense deposits that can be machined

• Free-flowing for thin lapping and butted metal joining

• No base metal dilution making tough cast iron repairs possible

“True Color Match” Cast Iron

Tensile Strength: 53,000 PSIHardness: Rc 18-20Bonding Temperature: 2,300°F (1,260°C)Recommended Flux: F22

Typical Applications

• Sheet metal and auto body repairs

• Engine heads and blocks

• Piping, plumbing and pumps

• Gears, sprockets and pulleys

Usage ProcedureUse neutral flame and preheat broad area along braze line. Concentrate flame on rod end and allow weld drops to flow on joint. Continue heating until it wets out and continue process. If a second layer is required, hold torch parallel to the work and apply drop-by-drop. When working with cast iron, avoid localized heating and cover finished braze to retard cooling process.

Technical Specifications

| Item#: | CW3062 |

|---|---|

| Welding Process | Brazing |

| Type | Bare |

| Diameter | 3/16 " |

| Length | 18 " |

| Tensile Strength | 53,000 PSI |

| Melting Temperature | 1560-2000 °F |

| Color | Gray |

| Base Metal | Cast Iron |

| Recommended Flux | F22 |

| UNSPSC #: | 23271804 |

| TAA Compliant: | No |

| Weight: | 5.0 lb |

Product Restrictions

California Proposition 65: Not Applicable

www.P65Warnings.ca.gov